Industry news|2022-03-04| admin

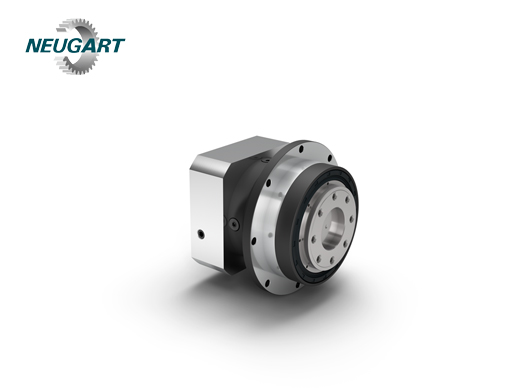

Servo precision planetary gearbox is a mechanism that uses gears for deceleration to increase torque, decelerates the number of revolutions of the motor to the required number of revolutions, and obtains a larger torque. Among the mechanisms currently used to transmit power and motion, the application range of the gearbox is quite extensive. Its traces can be seen in almost all kinds of mechanical transmission systems, from ships, automobiles, locomotives, heavy machinery for construction, processing machinery and automated production equipment used in the machinery industry, to common in daily life. Appliances, etc. In the work, the servo precision planetary gearbox will inevitably have some kind of failure, so how should it be repaired? What is the repair process?

Start by checking:

1. Bearing inspection. Rinse with heated mineral oil until the inner race is not snapped in any position by turning it gently by hand. After cleaning, check the bearing clearance with a feeler gauge.

2. Gear inspection. The gear must not be broken, and the tooth surface must not have cracks or peeling.

3. Check the shaft. The ovality and taper on the shaft diameter shall not be greater than 0.015~0.025mm. The surface roughness of all mating dimensions of the shaft conforms to the technical requirements of the drawing. The excess of 0.02mm can be reused, and the more than 0.02mm needs to be repaired before use. The axle width dimension does not exceed 0.04mm and can be reused, and if it exceeds 0.04mm, it should be replaced.

4. Check the gearbox box. Bearing cap.

And then the disassembly:

1. Clean the slime on the gearbox, hang it on the waste oil point to drain the oil and drain the waste oil.

2. Unscrew the connecting plate, bearing cover, gearbox interface bolts, and tile cover bolts.

3. Knock off the conical fixing pin, and lift the gearbox box cover with a crane.

4. Remove the high-speed shaft. passive axis.

After finding the cause, it is the right medicine. After this series is completed, it is the assembly acceptance.

Assembly:

1. Install the passive shaft, three-axis, two-axis and high-speed shaft in sequence.

2. Adjust the gear backlash and axial clearance.

3. The joint surface of the servo precision planetary gearbox is evenly coated with sealing glue; the other box of the gearbox is closed; the conical fixing pin is tightened;

Test acceptance suggestion:

1. For the upper motor, reduce the machine and add N120# industrial gear oil.

2. Power transmission test machine, the time is not less than 30 minutes.

3. During all the running process, the running should be smooth, no impact, no abnormal vibration and noise, no oil leakage or oil leakage at the seals and joints.

4. Observe the temperature of each part. Sound, no abnormal noise, bearing temperature does not exceed 40 ℃, no oil leakage on the interface surface and rotating parts.

Maintenance tips for servo gearboxs.

1. The lubricating oil used by the equipment cannot be mixed. The positions of the oil level plug, the oil drain plug and the fan are determined by the installation position.

2. For the plug equipment with oil level, it is necessary to check whether the oil level is qualified and install the oil level plug.

3. The oil will increase after cooling, and it is difficult to drain the oil. When changing the oil, it must be carried out when the equipment has a certain temperature. Also pay attention to cut off the power supply to prevent electric shock.

Servo planetary gearbox.

4. The oil quantity needs to be consistent with the installation position, and the oil level screw plug and fan should be tightened. When draining oil, place the connecting plate and open the oil level plug, fan and oil drain plug.

5. It is necessary to check the oil level, check whether the oil level is full, and install the oil level plug.

6. Take a sample to check the viscosity index of the oil. If the oil is noticeably cloudy, it is recommended to replace it as soon as possible.